What Is Circular Economy

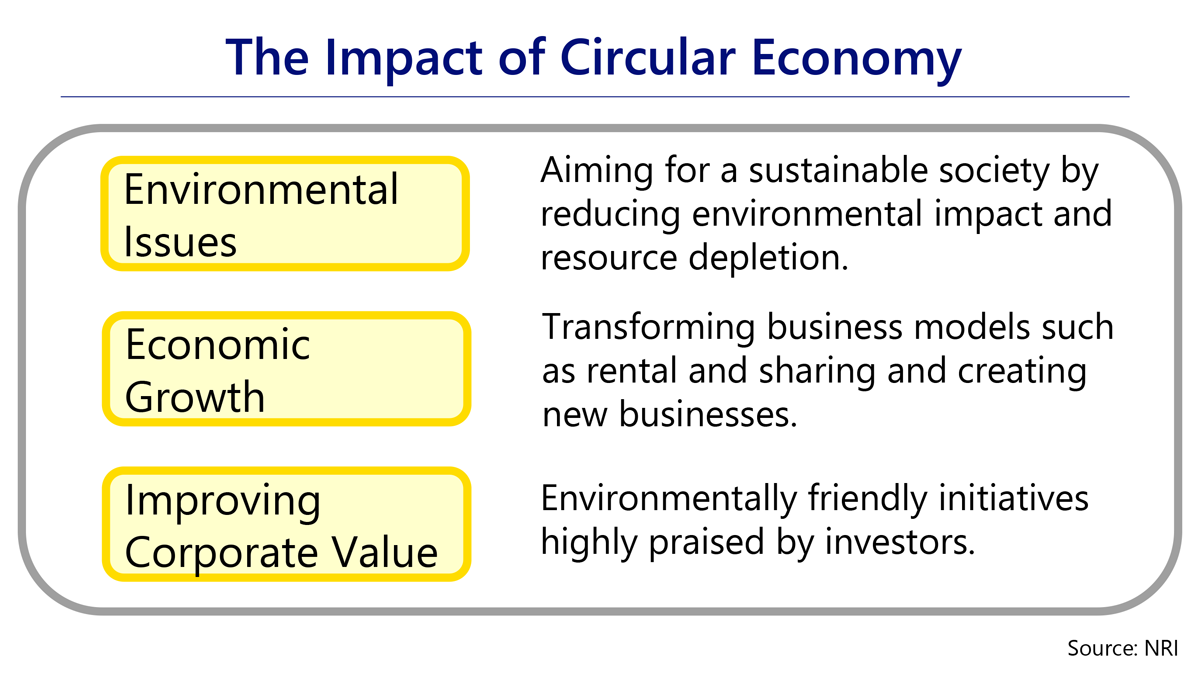

Circular Economy is an economic activity that reduces resource input and consumption, makes effective use of existing resources and products, and creates new value through services, in addition to 3Rs of "Reduce", "Reuse", and "Recycle". Circular Economy aims to create a sustainable society.

Why we need to shift to Circular Economy

Society today is aiming to achieve sustainable economic activity by maximizing the value of resources and products, minimizing resource consumption, preventing waste generation, and regenerating nature and natural resources.

In a society of mass production, mass consumption and mass waste, resource depletion, environmental pollution, and climate change due to greenhouse gas (GHG) emissions are already global issues.

In a linear economy that manufacturing and recycling industries are separated, the cost of recycling exceeds the value of recycled materials, resulting in situations that products or materials have been discarded even if they have resource potential.

It is important to transition to a Circular Economy that uses resources sustainably.

Linear Economy and 3Rs

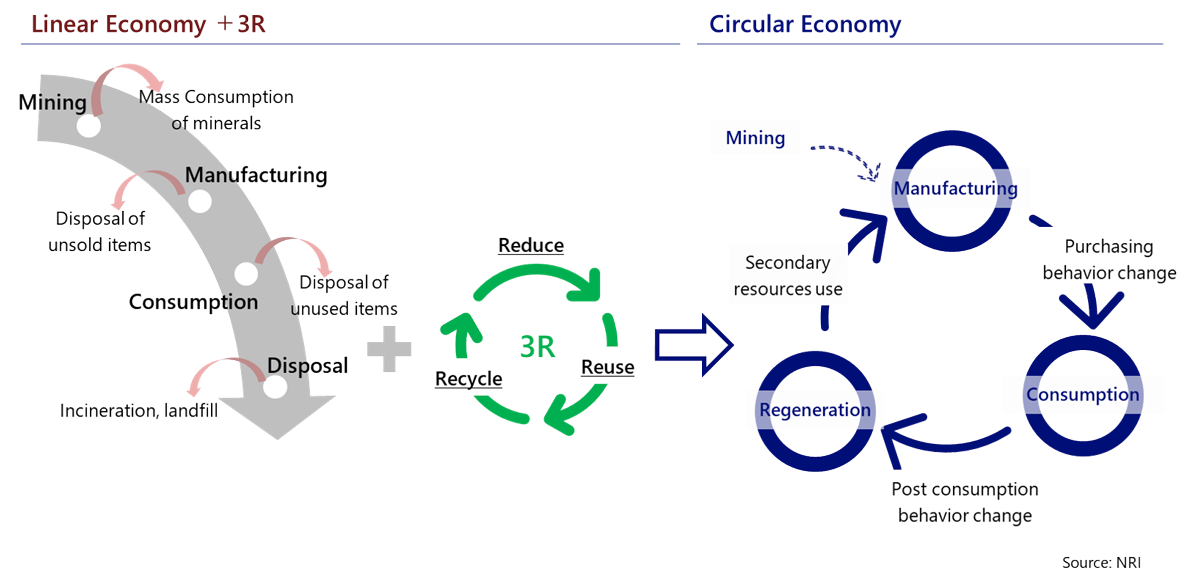

Circular Economy is proposed as a new socioeconomic system to replace the Linear Economy of mass production, mass consumption, and mass waste.

Linear economy is a unidirectional socioeconomic system of "Resource extraction or Mining→ Product Manufacturing → Consumption → Disposal". As the population grows and living standards improve, production, consumption, and waste have steadily increased, resulting in issues such as waste generation exceeding processing capacity. To address these issues, 3Rs (Reduce, Reuse, and Recycle) have been promoted.

While 3Rs have proven effective in addressing waste-related issues, other issues recently have also emerged, such as resource depletion and environmental pollution associated with mass production and mass consumption, as well as climate change due to greenhouse gas (GHG) emissions.

In addition to environmental issues or resource depletion, various forms of resource procurement risks are increasing, such as the trend toward economic blocks (restrictions on the import and export of resources across regions and countries) that is progressing in regions and countries around the world. In response to these issues, it is important to address not only the traditional 3Rs that focus on "mass waste," but also "mass production and mass consumption."

Change Business Model by Circular Economy

The way manufacturers operate, which has traditionally focused on the production and sale of products, is beginning to change.

In addition to 3Rs, the concept of refurbishing and remanufacturing has recently gained attention, in which manufacturers collect and refurbish used or defective products and reship them in near-new conditions. It is believed that if manufacturers can maximize service opportunities as added value by maintaining customer contact throughout the product lifecycle to ensure the functionality and durability of products (or parts), and understanding customer needs, this could lead to highly profitable businesses.

Furthermore, given this background, there are examples of businesses achieving Circular Economy by shifting from a one-time product sale model to a service provision model such as subscription or sharing (home appliance rental or car sharing).

Circular Economy is Industrial Perspective rather than Environmental Policy

The European Union (EU) announced "The Circular Economy Action Plan" as its policy guideline in 2015 and subsequently positioned Circular Economy as a key policy in "The European Green Deal" formulated by the European Commission (EC) in 2017. This was followed by "The Circular Economy Action Plan" in 2020, and more recently "The Ecodesign for Sustainable Products Regulation" which incorporates regulations covering the entire lifecycle of products, including design, durability, repairability, and recycled content.

Furthermore, for specific products, "The Packaging and Packaging Waste Regulation" which stipulates the recycling, minimization, and reuse of packaging, and "End-of-Life Vehicles (ELV) Regulation" which regulates the entire lifecycle of automobiles, have been published.

While these policies aim to reduce environmental impact, they also position themselves as industrial policies that enhance the EU's industrial competitiveness by making compliance with regulations regarding raw material sourcing and product design mandatory requirements for market entry, changing manufacturing practices and market rules. China also published its "The 14th Five-Year Circular Economy Development Plan" in 2021, and similar trends can be seen in countries and regions outside the EU.

In Japan, the Ministry of the Environment published "The 4th Fundamental Plan for Establishing a Sound Material-Cycle Society" in 2018, which mentioned economic aspects in addition to the traditional environmental aspects. In recent years, the Ministry of the Environment also published "The 5th Fundamental Plan for Establishing a Sound Material-Cycle Society" in 2024, and the Ministry of Economy, Trade and Industry also formulated "Growth-Oriented Resource Autonomous Economic Strategy" in 2023, both of which are notable for incorporating many elements of industrial strategy.

The Key to achieving Circular Economy is Information Collaboration

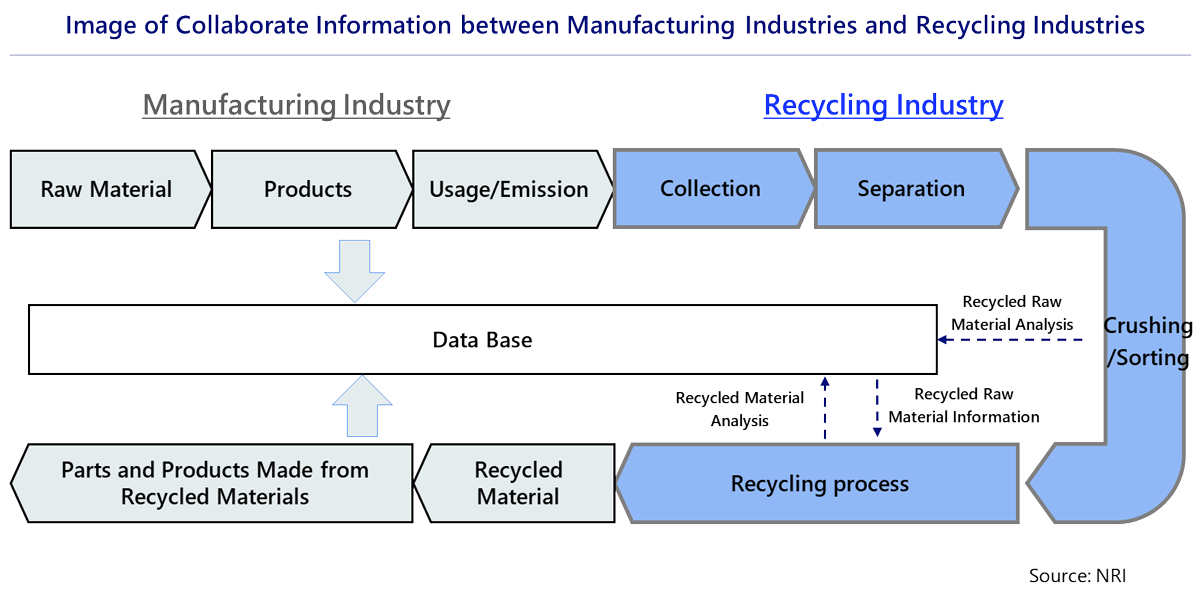

Achieving Circular Economy requires policy regulation and guidance. Realizing business requires not only technological development by specific companies but also collaboration among a wide range of stakeholders.

Collaboration across the entire value chain is required, involving both "Manufacturing Industry", which develops and manufactures materials and products, and "Recycling Industry", which handles processes such as sorting and recycling of collected materials and waste.

Minimizing information gaps between the Manufacturing and Recycling Industries is crucial for efficient collaboration across the entire value chain, and the distribution of various information related to manufacturing and recycling is essential.

Specifically, competitive concerns should be taken into consideration, if manufacturers share information on the composition, properties, history of use, and chemical constituents of the materials in their products with recycling industries, it will help recyclers improve the efficiency of recycling and preserve material and product value.

Recycling Industries can increase trust in recycled materials and promote their use by collaborating information on the traceability of the recycling process and the composition and characteristics of recycled materials with Manufacturing Industries.

It is need that common rule as common language that allows stakeholders participating in the information distribution platform to operate.

Profile

-

Mayuko TaniguchiPortraits of Mayuko Taniguchi

Consulting Business Development Department

* Organization names and job titles may differ from the current version.