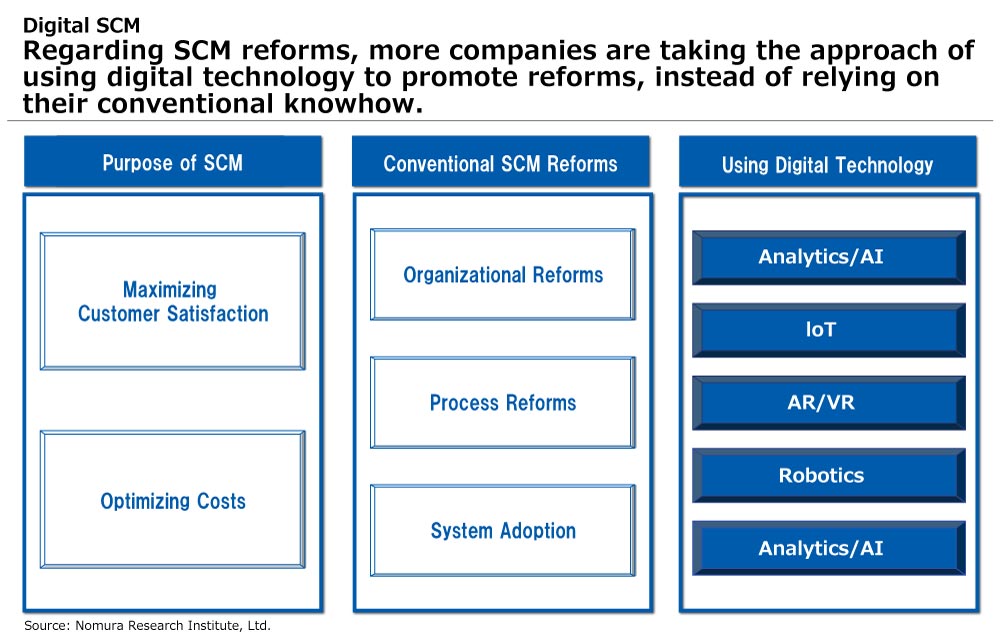

Supply Chain Management (SCM) Reform

NRI’s approach to supply chain value creation and planning involves diagnosing the state of a company’s current supply chain, considering its products’ features with their desired growth markets, logistical features, and all other relevant details. NRI collaborates with clients in assembling a comprehensive reform plan encompassing all functions, from new product development to after-sales services.

Supply Chain Design

NRI uses digital solutions to visualize the customer’s supply chain and then determine the optimal solution for its existing model, based on current supply chain requirements and performance results data. We also design ideal versions of supply chain networks that elicit maximum value by simulating multiple scenarios such as alternate distribution sites changes in site capabilities.

Product Lifestyle Management (PLM) Reforms

In manufacturing, PLM is a powerful factor in determining the functional requirements for the various processes in a company’s supply chain. Frontloading the product development process and establishing an optimal development process based on product value has become somewhat unavoidable in today’s global market.

NRI begins with analyzing product development processes and finds ways of boosting business value. We support companies making these reforms with the necessary digital technology and system-related measures.

Formation of S&OP Processes

Many companies undertake planning and inventory visualization projects as part of their global efforts to upgrade their planning. Some even build full-fledged processes covering demand-forecasting, formulating supply-and-demand plans and optimizing their inventories. However, even the most prepared companies are at risk of losing advantages if they fail to reform these processes to changing markets.

NRI supports companies facing this situation by equipping them with the ability to achieve reforms based on their own methodologies. By analyzing their PSI situation, NRI helps companies create the optimal planning and performance monitoring features, develop functions for monitoring production-related and logistical changes occurring in the market as well as internally shifts, and developing a holistic S&OP process.

Procurement Reforms

Process Reforms

During times of market volatility or economic fluctuation, companies look to modify their procurement processes by cutting costs in order to preserve competitiveness. Companies often realize during this evaluation period that they may not be working with ideal procurement partners.

NRI supports this evaluation process, assisting companies gain an advantage in their procurement. For directly procured materials, we create new processes for generating performance indicators and running simulations that are coordinated with PLM processes. For indirectly procured materials, we help carry out organizational and process-related reforms that not only reduce costs but also enable such reductions to continue indefinitely.

Direct Material Procurement Process Reforms

In the manufacturing industry, 60% to 80% of costs come from directly procured materials. Reforming the procurement process for such materials, therefore directly ties into improving a company’s cost competitiveness.

NRI supports companies in implementing methodology-based data analysis and process reforms to link their new product information and procurement information within their design and development process.

Indirect Material Procurement Process Reforms

Managing material procurement in an integrated, cross-functional manner faces considerable challenges. In assessing these challenges, it is difficult to judge whether material costs can be reduced through in-house efforts as these items and services customarily grow more expensive.

NRI helps companies diagnose their cost cutting and to achieve a “quick win” by curbing costs in a short timeframe. During this reform process, we also help companies build the systems and processes they need to create their own sustainable low-cost operations.

Logistics Reforms

As companies expand their businesses globally, following a resolute methodology for analyzing and visualizing their networks and building a material handling process system for global distribution is a crucial element.

NRI helps companies visualize their distribution sites and map out which logistics-related factors are truly essential, which boosts productivity and optimizes inventory.

Logistics Digitization

Once distribution site conditions are visualized and the right methodology is established, the next step is to ensure that the sites are efficient and offer greater value through digitization.

Establishing on-site reforms that involves systematic automation, labor-saving operations, and the use of big data is crucial. NRI helps with the digitalization of operations and formation and implementation of measures in line with on-site situations.