Digital Mid-Term Planning: The business transformation handbook for surviving in the manufacturing industry

As the world moves toward business innovation through the use of digital technologies, we will restructure corporate business models from a strategic perspective

With digitalization, business models and their provided value are being questioned

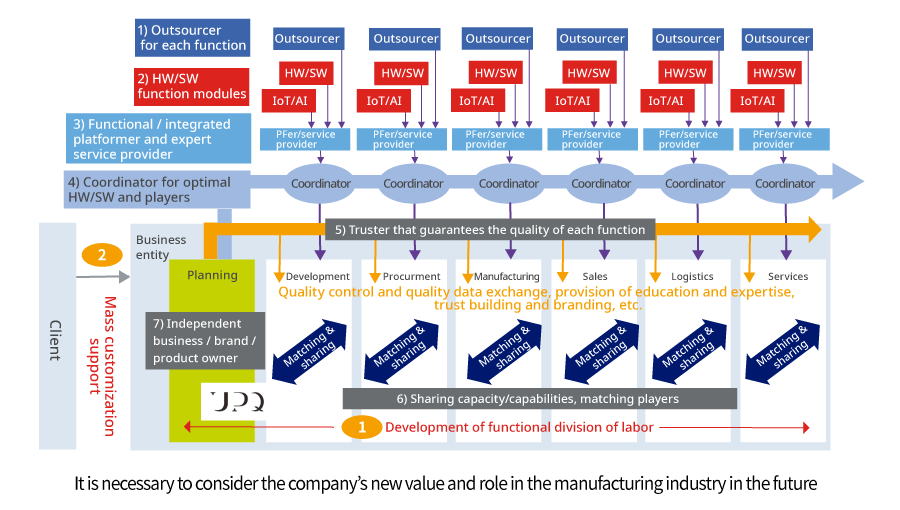

Digitalization of industries has begun in earnest all over the world, such as Germany's Industry 4.0 and China's Made in China 2025. The manufacturing industry, which has been in charge of everything from development to manufacturing and sales, is about to undergo major changes with the development of digital technology. For example, new value providers are emerging, such as line builders that handle the design, procurement, and installation of plants and lines as full turnkey operations, platformers that provide services by integrating various functions such as development, manufacturing, and services with software and IoT, and servicer providers that share their in-house expertise with platformers. In the midst of these functional divisions, the business model and the way in which value is provided by the manufacturing industry through the use of digital technology is being tested more than individual technologies and functions themselves.

Japanese companies, with their local and short-term approach, remain stuck at trying to visualize the workplace

Japanese companies have limited their efforts to local optimization, and most of them are yet to take steps to upgrade their management and business models. The background for this is as follows:

-

□

Studies restricted to local level due to lack of leaders who grasp the overall picture

- ・

Gaps in business scope, capabilities, and understanding among the management, business, and IT departments, and tendency to form organizational silos

- ・

-

□

Short-term investments due to RoI uncertainty and risk aversion

- ・

Reluctance to invest in businesses that take time to become profitable (PF businesses, etc.) and those in which the RoI is not clear (data infrastructure development, etc.)

- ・

-

□

Lack of open innovation and insistence on technical PoC

- ・

Focus on closed innovation, vendors' goodwill and past performance

- ・

Lack of perspective on business model PoC using technology

- ・

■ Disruption of the manufacturing industry value chain and creation of new value due to digitalization

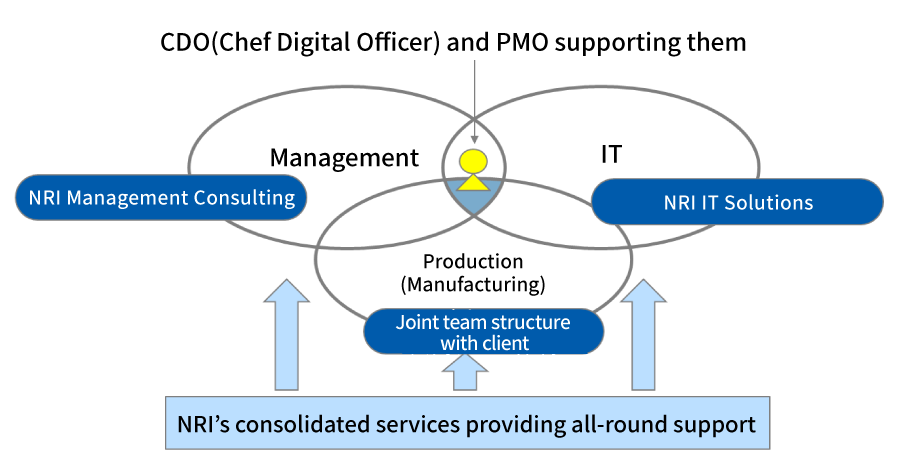

NRI supports the formulation of mid-long-term business transformation strategy, as well as determination of policy steps, roadmap, and organization design for digital transformation

Support for strategic changes, policy roadmap formulation, and organizational design with digitalization

When considering business transformation and management strategy based on digitalization, it is important to consider the questions of what we would actually achieve and what kind of business model we would like to build, rather than the technology itself.

With our digitalization-based approach to business model transformation and deep understanding of the current status of manufacturing industry operations and the obstacles therein, we provide support for business model and business transformation through the use of digital technologies, from strategy to policy formulation and organizational design promotion. Along with working to establish consensus regarding strategy formulation among executives and management, we support the formulation of action plans for the implementation roadmap through in-depth discussions with key division heads and department/section managers. We will then help in designing a smooth organizational structure, including fostering leaders to execute those strategies and actions, as well as operations and governance.

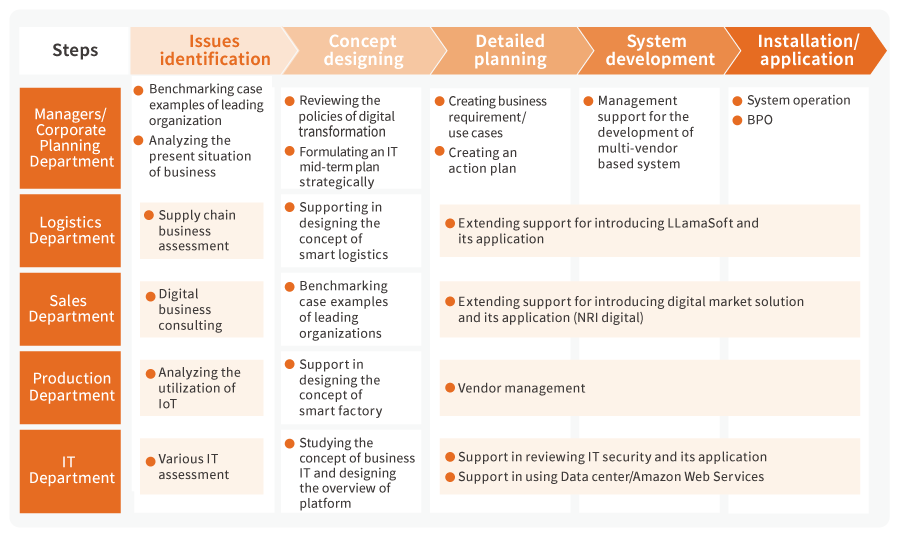

Case study: Support for the formulation of a company-wide mid-term digital strategy for a Japanese auto parts manufacturer

NRI helped a Japanese auto parts manufacturer to formulate a company-wide mid-term digital strategy. In the strategy phase, we established a long-term digital management strategy, including the ideal business model and value to be provided, through a training camp for executives. This was done keeping in mind the changes in the structure and competitive environment of the client's industry due to digitalization.

In the formulation phase, we used the above outline to create a roadmap for implementation of measures through discussions with key division heads and department/section managers. Based on the results obtained, we established a mid-term digital strategy and defined the roles of all executives at the training camp. We then assigned digital promotion executives and designed organization structure and teams to implement each of the measures respectively. Thus, by creating a forum for executives and key personnel to agree on strategies and action plans for digitalization and designing a smooth organizational structure, we smoothly formulated the digital mid-term management plan.

■ Characteristics of NRI's Digital Mid-Term Planning Service

Increasing the productivity of white-collars “RPA”

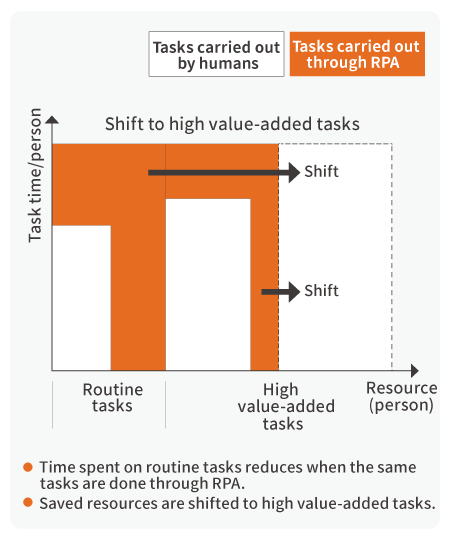

Initiatives are required to improve the productivity of white collar workers by delegating the routine tasks to a robot (RPA).

In addition to improving productivity, RPA will also develop services linked with AI in the future

Japan's working age population is declining and Japanese organizations need to take countermeasures for continuous labor shortage.

Following that, Robotic Process Automation (hereinafter, referred to as RPA) that can automate the routine tasks is drawing attention. RPA is a technology to automate routine tasks that require humans to perform on computer screens with a computer robot. Since 2016, financial institutions and service industry in Japan that have many routine tasks to do have been adopting RPA solution. As a result, RPA helped in shortening the time, enhancing the tasks and improving the quality of tasks (reduces mistakes). Going forward, it is expected that this technology can execute higher-level tasks by linking it with the development of AI related technologies.

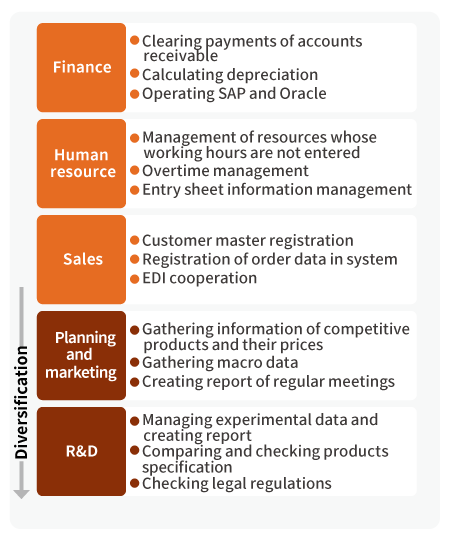

RPA will be introduced in the R&D activities of manufacturing industry

Since 2017, RPA has been introduced in various industries. The success stories concerning RPA can be witnessed not only in the domains, such as general affairs, human resources, finance, and back office tasks, but also in R&D activities of manufacturing business. In the R&D department, there is always a resource crunch of development engineers. As an instance, it was anticipated that RPA will be introduced in routine tasks such as transcription of experimental data by engineers. Moreover, RPA is becoming more widespread in cases where there is a mismatch between the human resources and the operations being performed, such as routine tasks being performed by management-level workers.

Even in the R&D department, there are examples where the routine tasks were automated through RPA and it is expected that through this, the saved resources can be put to higher value-added tasks.

■ Results of introducing RPA

■ Diversification of tasks where RPA is introduced

NRI provides integrated solutions, from formulating a plan for RPA implementation to its development and carrying out operations with an aim to bring workstyle and digital reforms.

We support creation of an ideal organization that promotes business reforms using RPA as production site initiatives

One of the advantages of RPA is that it is easy to use. Until now, the RPA was introduced by only information system department to develop IT systems, but now it can also be introduced under production site initiatives. RPA can transform a workplace into an ideal organization that enables employees to improve their work efficiency.

However, the ease of introducing RPA may backfire as it involves various risks, where RPA developed at the production site can put load on the server, causing the server to slow down, and can increase management cost when different tools are used by different departments. Moreover, there is a risk that RPA may collect or misuse the confidential information of the company. Therefore, for company-wide deployment of RPA, it is necessary to establish its control rules.

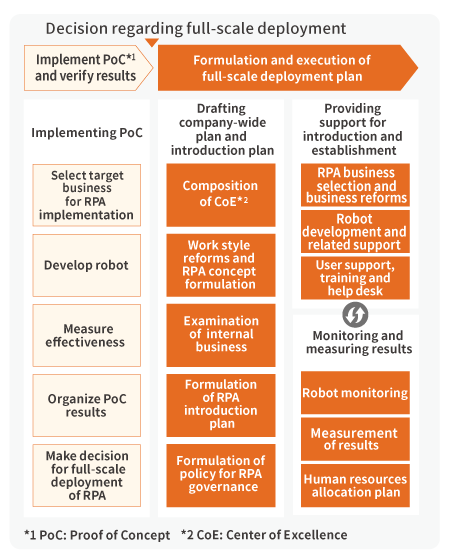

NRI provides integrated solutions, from formulating a plan for RPA introduction to its development and carrying out operations after considering the risks peculiar to RPA.

Case: Effective to build and operate a centralized system ‘CoE’ that allows smooth introduction of RPA

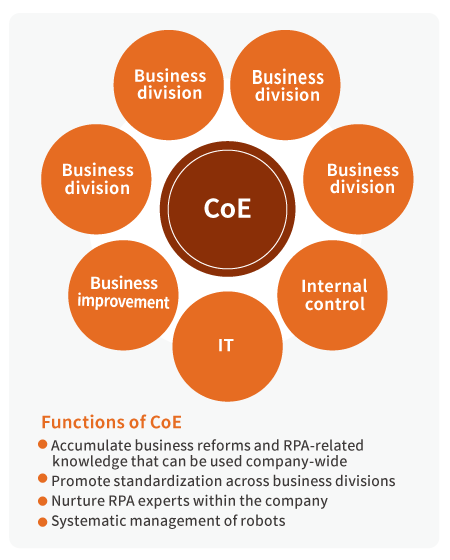

In order to implement RPA, in addition to the production site and IT departments, it is essential to cooperate with the operational reform divisions as well. NRI aims at effectively introducing RPA at necessary locations by treating RPA as a tool of business reformation rather than setting the number of robots in KPI.

In order to promote RPA utilization and improve operations throughout the company, NRI has been proposing continuous business improvements beyond the introduction of the RPA tool, we have built the center of Excellence (CoE), which is a dedicated group of professionals required for reformation. CoE aims at systematically managing the knowledge of RPA gathered at each production site as explicit knowledge to be accessed in entire organization. It can prepare for risks by centralizing company-specific governance matters. Through this, companies will be able to deploy business improvements and utilize RPA throughout the company using knowledge accumulated in CoE.

■ RPA introduction process in NRI

■ Specialized units for business improvement and RPA introduction form

Total value chain design in the digital age “Supply chain update”

An era where each component or customer can be identified.

Functions need to be strengthened across complete supply chain.

Following Industry 4.0, corporate management started collaborations with the emergence of new digital technology such as IoT

With the advent of IoT and Big data processing technology, it is possible to identify each component, manufacturing plant and customer. In Germany, the industry, government and academia are working together to promote "Industry4.0" and use these digital technologies to bring about innovations in the manufacturing sector. As a result, the horizontals of IT competition principles are added to the vertically integrated manufacturing competition principle and if there is no ability to quickly incorporate the "best practices" developed outside company into company's own management or business process, it will make the company less competitive compared to other companies.

The vision and speed to incorporate the new methods of competition while using company's strength will become one of the competition ability of an organization.

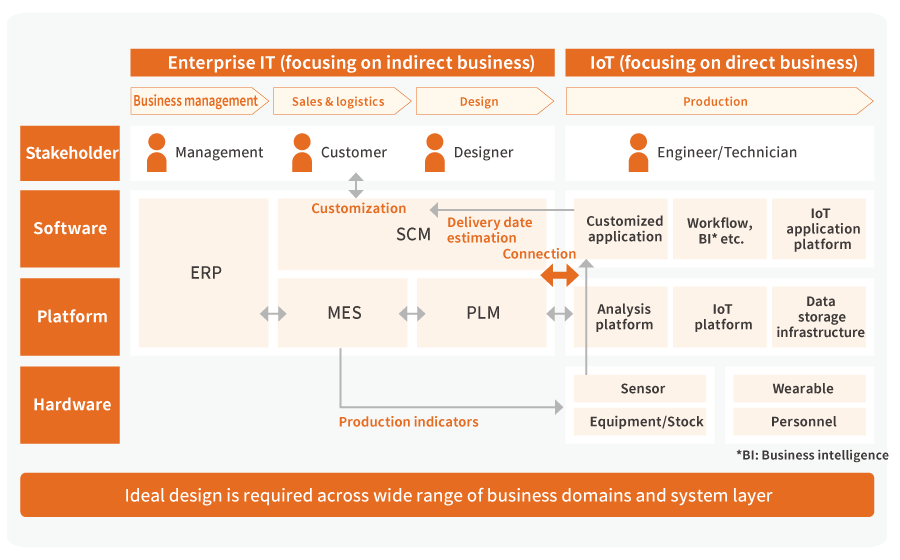

Need to design new business and system for the entire supply chain

Mass customization is an example of close cooperation between management and digital technologies. This is a way to prepare a huge menu of options so that each customer can be satisfied.

In order to implement the mass customization, it is necessary to have a flexible "procurement" from a wide range of suppliers, "production" capable of responding to specification changes for each item, "sales" to individual customers using digital channel, smooth "logistics" and a high level "system" that supports all of these.

Therefore, it is necessary to a design business and a system across the entire supply chain.

■ Integration of corporate management and new digital technologies such as IoT

NRI provides comprehensive support for supply chain updates with the help of consultants who have a deep understanding of the automotive industry and IT.

Consultants with deep understanding of automotive industry and IT, support the analyses of IoT utilization

The lack of "Business IT resources/team" that serves as an integral part for studying the collaboration between management and IoT has become a major challenge in many organizations. NRI has years of experience in executing various automotive industry projects and has amassed extensive knowledge of the industry. At the same time, system development division has been engaged in developing and operating IT platform and systems handling large amount of data such as securities and distribution.

We support implementation of digital technology at client's company by working together as a team with experienced consultants and IT solution providers. Even in the field of supply chain design, we can propose optimum vendor-free solution, from optimum consulting to proposal of system development using package software such as LLamaSoft.

Case: PMO support to study the use of IoT in factories

NRI implemented the PMO from concept formulation to vendor control for using IoT in factories.

First of all, we defined the significance of implementing IoT and formulated the concept of business and system "concept of systemization", we designed the PoC* to evaluate and understand the impact of IoT and supported vendor selection and negotiation. The person in charge of IoT at client company, mainly from Production Engineering Department, the business consultant of NRI, and the system consultant together formed the Business IT Review Team. Following the formulation of concept of systemization, we provided detailed usage scenarios to configure the full-fledged system and extended support to set the system requirements. While using the packages, we also carried out study and offered suggestions to ensure originality of an organization and freedom to select the IT vendors. NRI has experience in designing an IT mid-term plan that serves as connecting point between management strategy and IT plan and designing IT architecture concept to support the strengths of an organization so that system based concept can function effectively.

* PoC: Proof of Concept

■ Features of NRI’s service of providing the support in studying the use of IoT

Next-generation sales reformation using customer data “Digital Marketing”

While the disruptive digital marketing model is being implemented, there is an urgent need to make reforms in the next-generation sales model using analytics.

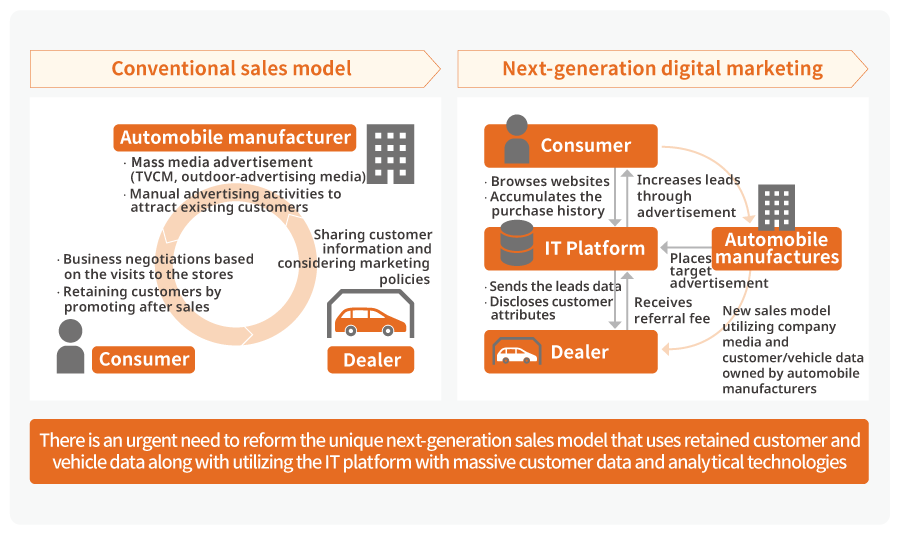

Disruptive business model of IT platform with massive customer data

Due to the rapid spread of IT services and portable terminals, digital information has a decisive influence on the purchasing behavior of cars, services, accessories, etc.

IT platform, a media of providing digital information has been causing a disruptive influence on conventional sales model by analyzing the massive data of purchasing behavior. For example, in China, IT platform anticipates the automobile purchases using the customer data, sends the data of high potential leads to dealers and receives the referral fee; hence, providing a potential solution of distribution and sales structure which were closed for conventional manufacturers and dealers.

While using the IT platform, it is necessary to build a unique next-generation sales model by using the customer and vehicles data of manufacturers and dealers.

Necessity of next-generation sales model using the analytics in retained customer data

On one hand, the preferences of customers are getting diversified and uncertain, the business of dealers is expanding and products are getting complicated. Providing a purchasing experience that meets the needs of customer is becoming increasingly complex.

Manufacturers and dealers have been accumulating the massive data of customers in the past. However, most of the data is not used and even if it is used, it is only used for call center response or sending the direct mails. There are many operations that rely on human effort and they are not in the state that can provide an individualized purchasing experience.

In order to implement a sales model that responds to diversified preferences, it is very much required to acquire more customer insights using analytics in customer data analytics.

■ Transformation in the structure of distribution and sales brought by digital marketing

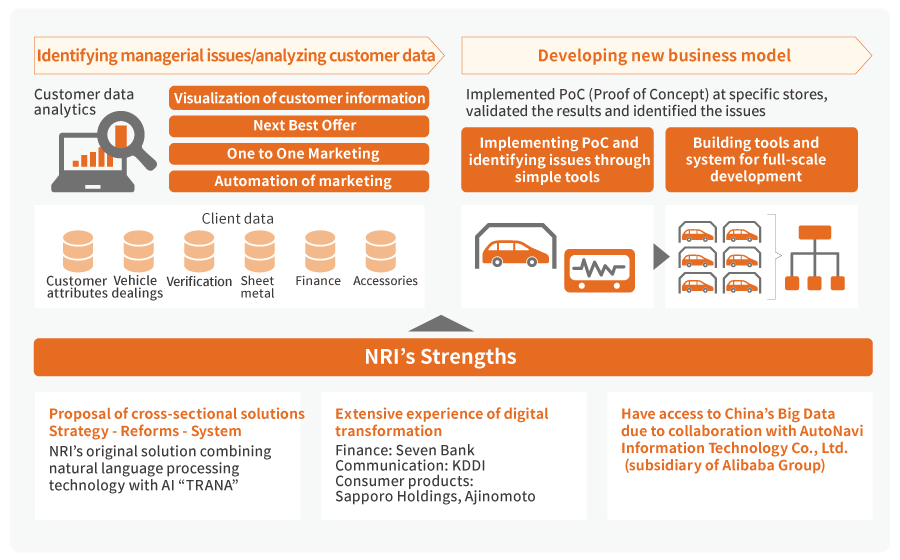

NRI supports the transformation of digital marketing using the analytics.

Supports in transformation, from analyzing data to implementing business reforms

NRI not only has extensive knowledge about automobile distribution and sales industry but also have extensive experience of providing integrated solutions and digital transformation, from management to IT. We also have strengths in making resilient improvement in sales model, such as access to big data by collaborating with AutoNavi Information Technology Co., Ltd. (subsidiary of Alibaba Group) in China.

NRI's data scientists ascertain business domains that utilize data very effectively to analyze the managerial issues, they use most appropriate analytics to respond to the issues and implement suitable analysis to create a connection between the store and the customer. We can also build a business structure from sale of new cars to providing after sales support in collaboration with AutoNavi in China.

In establishing a new business model, we provide support for identifying, correlating and fixing issues, and building a system for full-scale deployment, while implementing PoC (Proof of Concept) repeatedly.

Case: Anticipating “Potential customers” and support to increase the sales of dealers

Using our potential to offer consistent solutions, from identifying managerial issues to analyzing the customer data, we developed a model that anticipates highly potential customers who are likely to replace their cars by analyzing the past 20 years’ transaction data of dealers. We extended support to enhance and streamline the sales activities of dealers using this model.

In this case, we identified potential customers who are likely to replace their cars within a certain period of time and incorporated them into the business as an indicator for implementing the proposal activities of sales staff at production site. Anticipation on replacing the cars helped in ranking by probability and, we were able to use them as indicators to prioritize the activities for proposal.

In addition, we also developed a platform that supported timely implementation of marketing strategies by making the potential customer information that was only known by the sales staff at production site available to sales manager and sales headquarters as well.

■ Transformation in the structure of distribution and sales brought by digital marketing